Gap/Crash/Dress Acoustic Emission Systems

The use of Acoustic Emission Control brings not only shorter grinding cycles by using Gap control, but safety in the use of Crash control, and economy in the precise monitoring of Dress control.

MPM offer a wide range of Acoustic sensors for the detection of gap control, crash avoidance and dressing control.

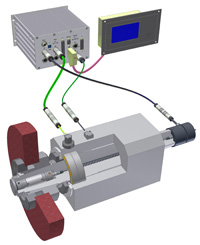

Typical example of Gap / Crash / Dressing control on an external grinding machine.

MPM Fluid Sensor offers users the ability to utilise Gap / Crash / Dress control where the use of conventional sensors becomes prohibitive.

A stream of coolant from the machine’s supply is directed at the component through the Sensor, and the AE signal is transmitted in the reverse direction to the coolant flow. The AE signal is then transferred from the Sensor to the process monitoring device to monitor and control Gap / Crash / Dress.